Roxchem Ltd

DROP-STOP

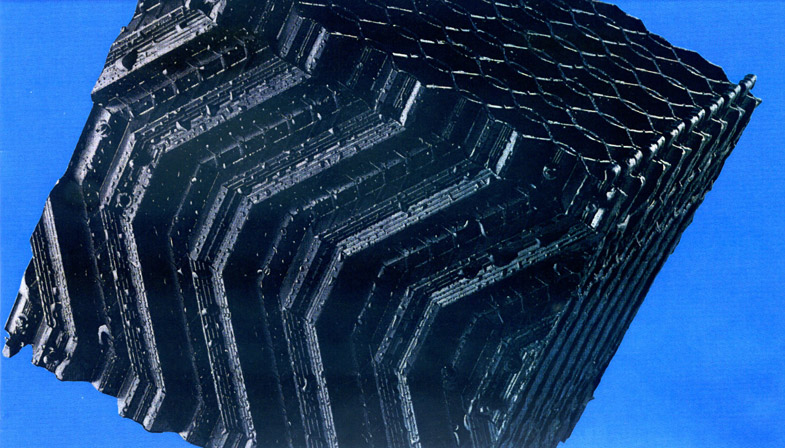

Drift eliminator

TYPICAL USAGE

DROP-STOP is a modern impact drift eliminator of the for the separation of liquids from aerosol.

DROP-STOP is typically used in:

• Gas washing and /or adsochers.

• Dehumidications of gases and/or vapor.

INSTALLATION

DROP-STOP offers the indicated performances when:

• It is installed with a minimum inclination of 45° on the level. However it is advisable to install it vertically,

refer the attached diagram.

• The gas stream flows in through the module regularly, without turbulence and at uniform speed.

• There are no preferencial ways.

• It is advisable that the drift eliminator be easily removed for control and maintenance operations.

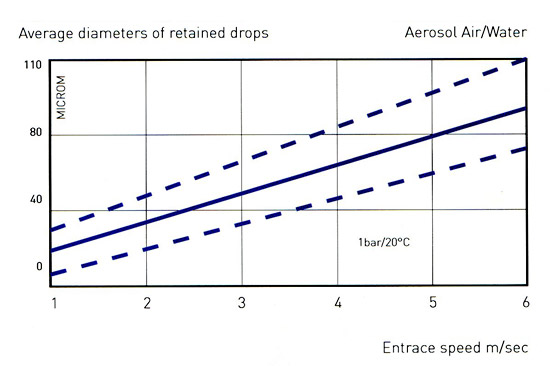

EFFIECIENCY

The efficiency considered as a percentage of liquids removed from aerosol, depends on many elements, which the main are:

• Dimensions and concentration of drops at the entrance of the module.

• Temperature and viscosity of the phases which compose the aerosol.

• "Maximum capacity" or "entrance speed" for the loading of the module.

For air/water aerosol at ambient temperature and pressure, the efficiency of the drift eliminator is shown in the diagram.

A "mormal" target is to keep drops with a diameter equal or smaller than 50 micron. In this case the water leak in the liquid phase is moer or less 0,4 - 0,5%. (per thousand) of the useful water flowrate for air washing. That is what happens provided the device is correctly installed.

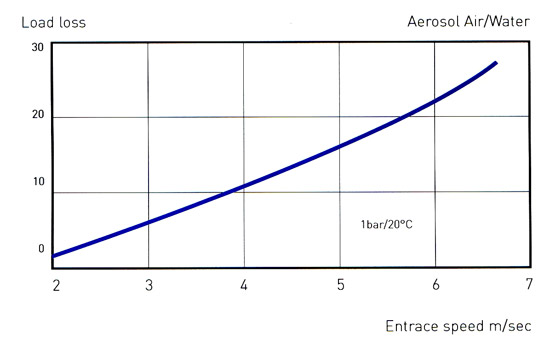

LOAD LOSS

Also the load loss depends on the already mentioned factors. As to the yield of water/air aerosol )under pressure and at ambient temperature), load losses are shown in the following diagram

The diagram shows (with ± 15% tolerance) only DROP-STOP drift eliminator load losses. Load losses due to other causes are not included (tower and pack container geometry)..